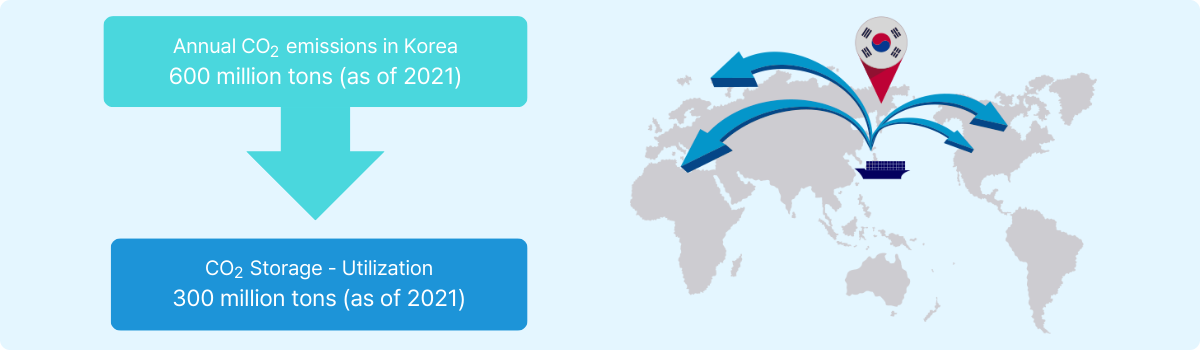

The captured and purified CO2 is stored in the form of liquefied carbon dioxide before being distributed to various industries. Although it is important to commercialize economical capture technology, building infrastructure to store CO2 is also essential. In the case of Korea, an ocean isolation space capable of storing 730 million tons of CO2 is proposed through continuous exploration and drilling, but it is insufficient to store the approximately 700 million tons of CO2 emitted annually. As an alternative to this, a blueprint is being drawn for purified liquefied carbon to be temporarily stored in a hub facility and then transported and stored overseas through a carrier. It is true that it is a method for storing massive amounts of CO2, but it faces the following problems.

EOR (Enhanced Oil Recovery)

- • Overseas distribution problems (war, virus, diplomacy, etc.)

- • Increase in demand (CO2 gas) compared to supply (place)

CO2 HUB

- • Geological space limitation and NIMBY

- • Safety issues such as explosions

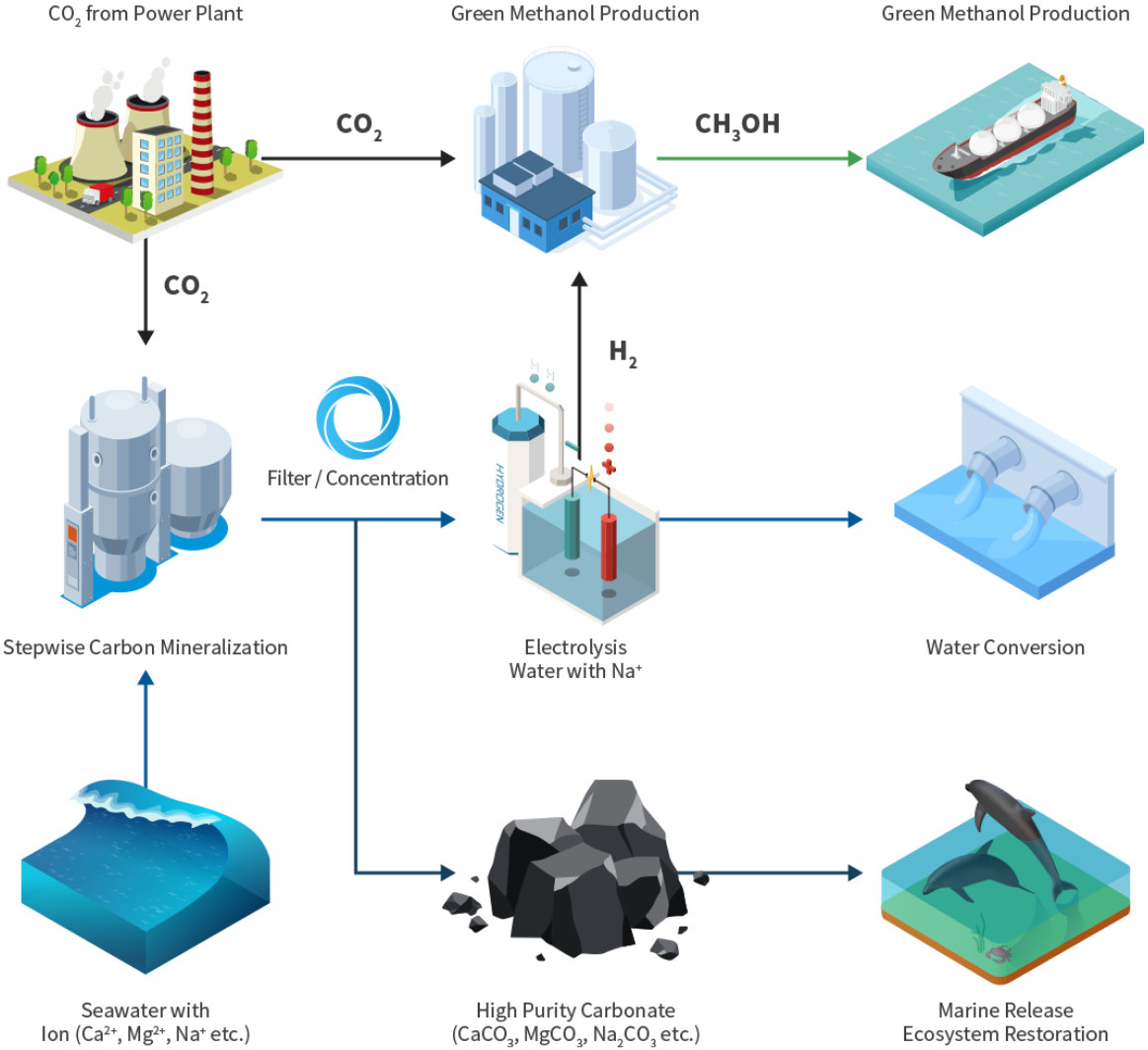

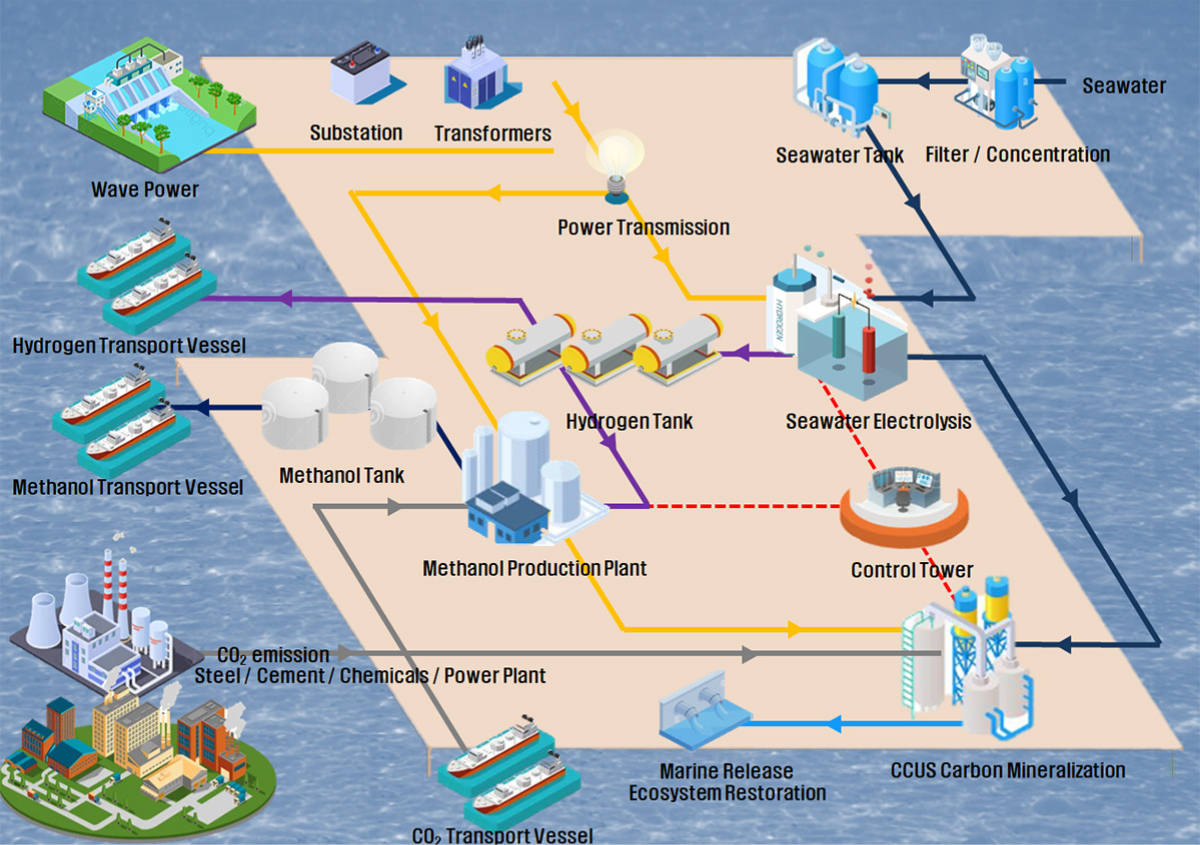

Purified CO2 can be used directly for carbonated water production, welding, dry ice, semiconductors, etc., but demand for it is very low compared to future supply. The value of CCUS is increased by applying technologies such as manufacturing and utilizing ceramic raw materials through step-by-step carbonate mineralization, isolation in deep ocean water according to environmental impact assessment, ship CO2 Capture and E-methanol synthesis.

New Industries using CO2

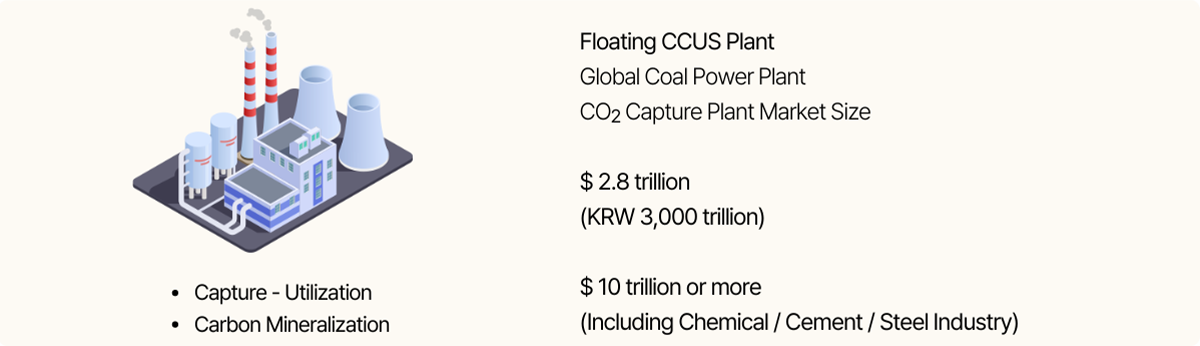

[1] Floating CCUS Plant

Utilization of world-class domestic shipbuilding technology – Floating CO2 Capture Plant (250MW,

500MW, 1000MW)

Reduced construction cost by 1/5 compared to onshore plants – Preoccupation in the global market

Construction Investment Cost : 250MW - $200 million / 500MW - $400million / 1000MW - $700million

- • Coal-fired power plants around the world : 7,000 unit (Operating + Under Construction)

- • Average construction cost of floating CO2 capture plant : $ 400 million (Based on 500MW)

- • Market size : 7,000 Unit x $ 400 million / unit $2.8 trillion (KRW 3,000 trillion)

- • 10% Market share $280 billion (KRW 300 trillion)

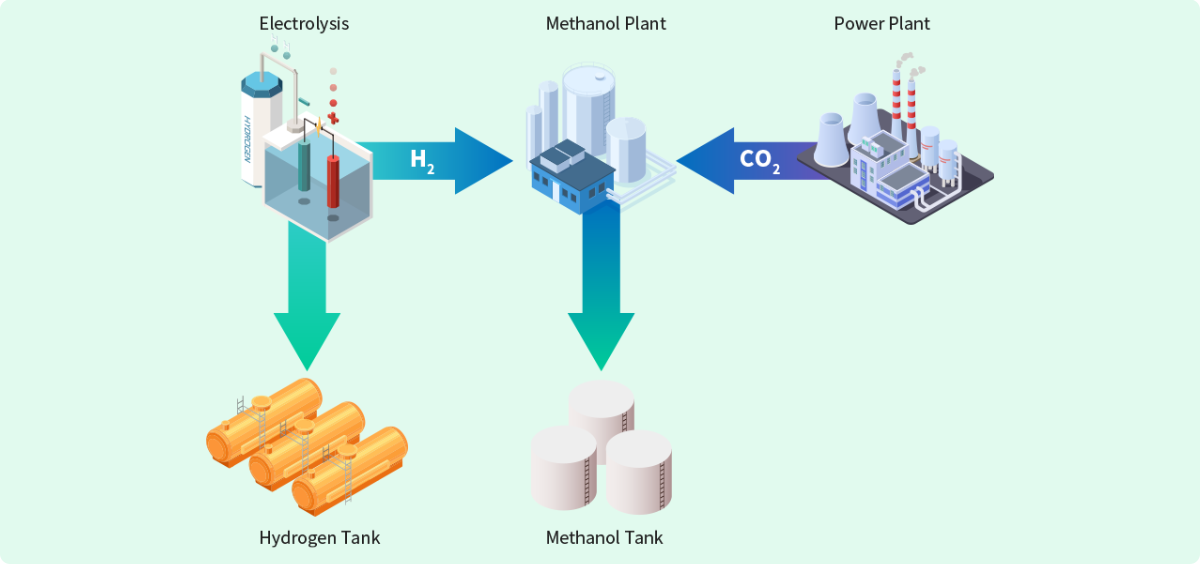

Hydrogen produced through seawater electrolysis can be used as new energy and can be converted into methanol through a chemical reaction with carbon dioxide. Green methanol and recycled methanol technology, which converts large amounts of carbon dioxide generated in chemical plants, power plants, and steel mills directly into methanol without syngas, are expected to contribute to responding to climate change. Methanol is used as a synthetic solvent as well as a raw material for the manufacture of various chemicals and pharmaceuticals. It is also used as a clean raw material for shipping ships and as fuel for methanol fuel cells.

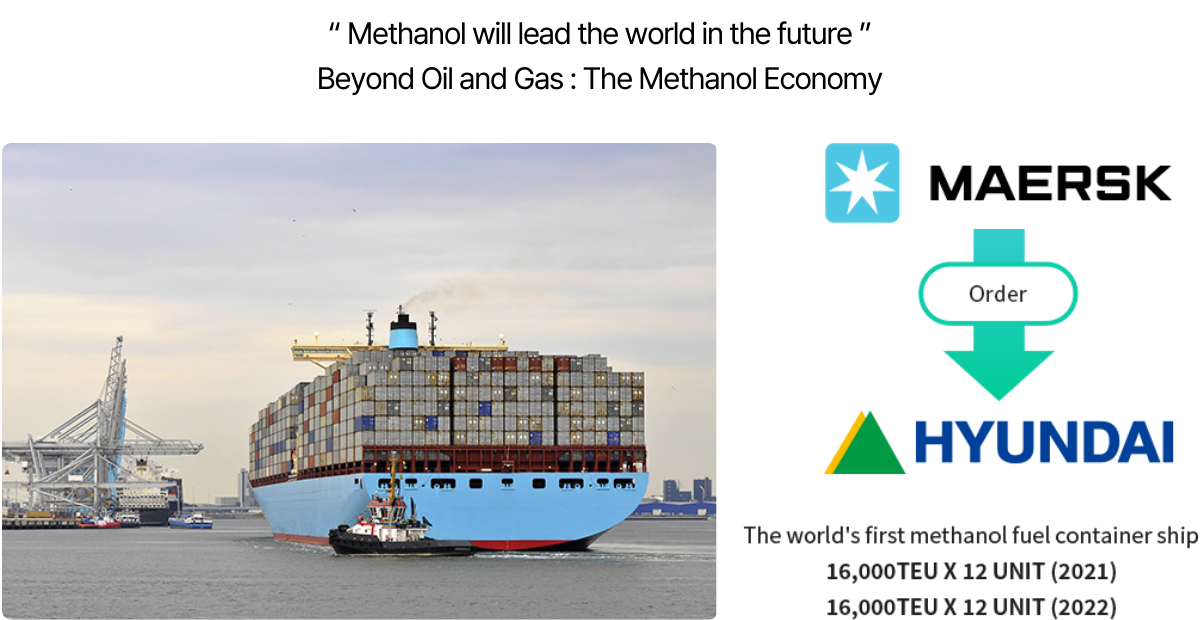

As the shipbuilding industry is accelerating the development and commercialization of next-generation

eco-friendly fuel for ships that will follow liquefied natural gas (LNG), ‘methanol-powered ships’, which will

serve as a stepping stone before the full-fledged offshore hydrogen market, are gaining momentum. Recently, as

global shipping companies are increasing orders for large container ships that use methanol as fuel,

competition for orders for methanol-powered ships is intensifying.

Previously, Musk, a world-class large shipping company, placed an order to Hyundai Heavy Industries in August

2021 to build eight 16,000 TEU container ships that use methanol as fuel by 2024 by 2024. Along with Musk, CMA

CGM, a global 'top 3' shipping company, recently announced a plan to place an order for six new 15,000

TEU-class methanol dual-fuel new ships.

Element technology : Wave power renewable energy using seawater / Hydrogen new energy through electrolysis / Methanol production through the synthesis of hydrogen and carbon dioxide / Carbon mineralization through the reaction of seawater and carbon dioxide / Ocean alkalization and ecosystem restoration through carbonate discharge