Currently, gray and blue hydrogen are being produced through extraction and reformation from fossil fuels.

(USD 1.2~2.2/kg depending on production method) Green hydrogen produced through renewable energy and water

electrolysis is three to four times more expensive than gray hydrogen. (USD 3.5 to 7.5/kg depending on

production method)

The amount of hydrogen produced annually in Korea is 2.34 million tons, and is 100% generated based on fossil

fuels. By increasing renewable energy generation and improving water electrolysis efficiency, the unit price

of hydrogen production can be lowered to $2.2/kg.

If electrolysis is performed using seawater, a semi-permanent resource, as the source of water, the cost of

artificially added electrolyte salts can be saved. However, under alkaline conditions, salts such as Mg and Ca

present in seawater form scale, which shortens the lifespan of the electrode and reduces electrolysis

efficiency.

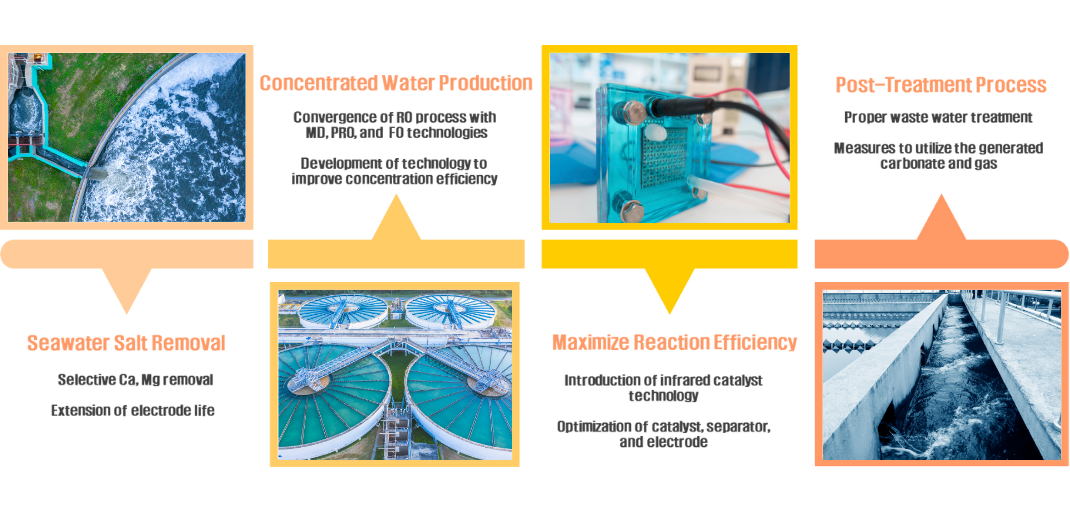

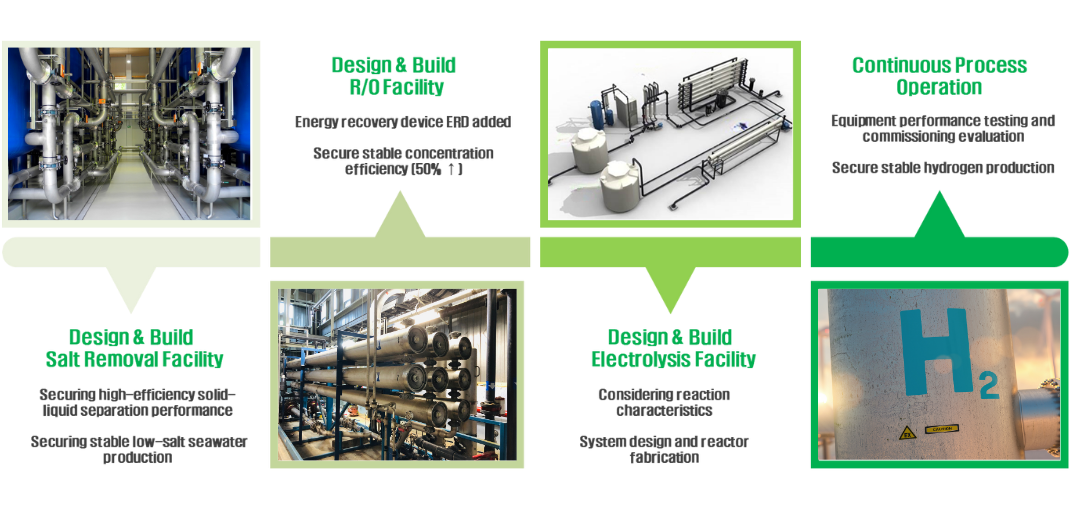

Electrolysis efficiency is maximized through the following processes.

1. Preliminary removal of Ca and Mg ions that can cause scale formation in seawater

2. Improvement of R/O technology using semipermeable membrane and hydrostatic pressure difference

3. Reduction of activation energy through introduction of optimized infrared catalyst

Seawater Desalination

It is a future technology that can be used as industrial water and even drinking water through seawater

electrolysis and additional treatment of the supernatant fluid after each step of carbonate production.