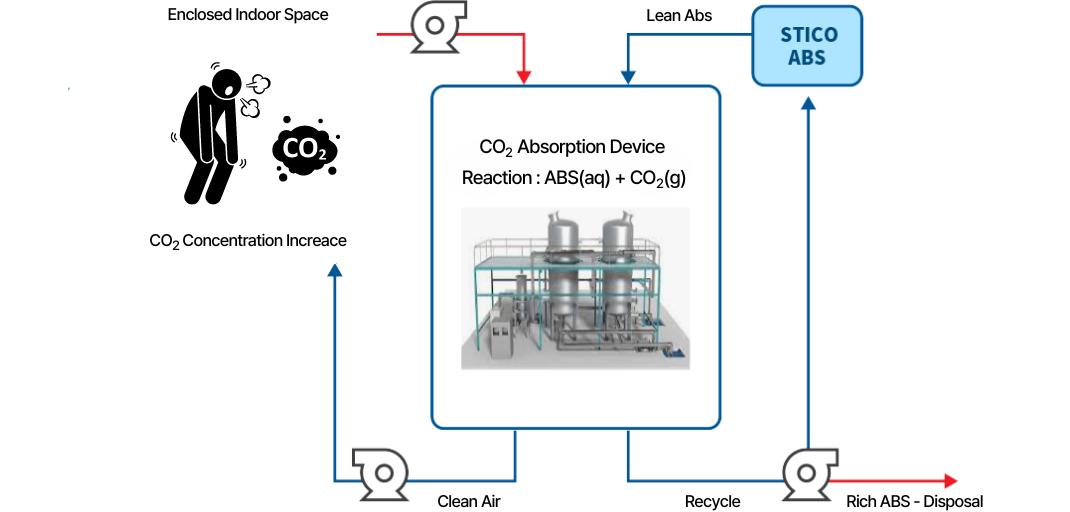

Using a CO2 removal device can improve the indoor air environment. (submarines, manned spacecraft, safe rooms, etc.) This allows normal breathing by capturing CO2 emitted from human breathing in a closed space in the short to medium term. Furthermore, CO2 generated from power plants, steel mills, and chemical industrial processes can also be selectively captured.

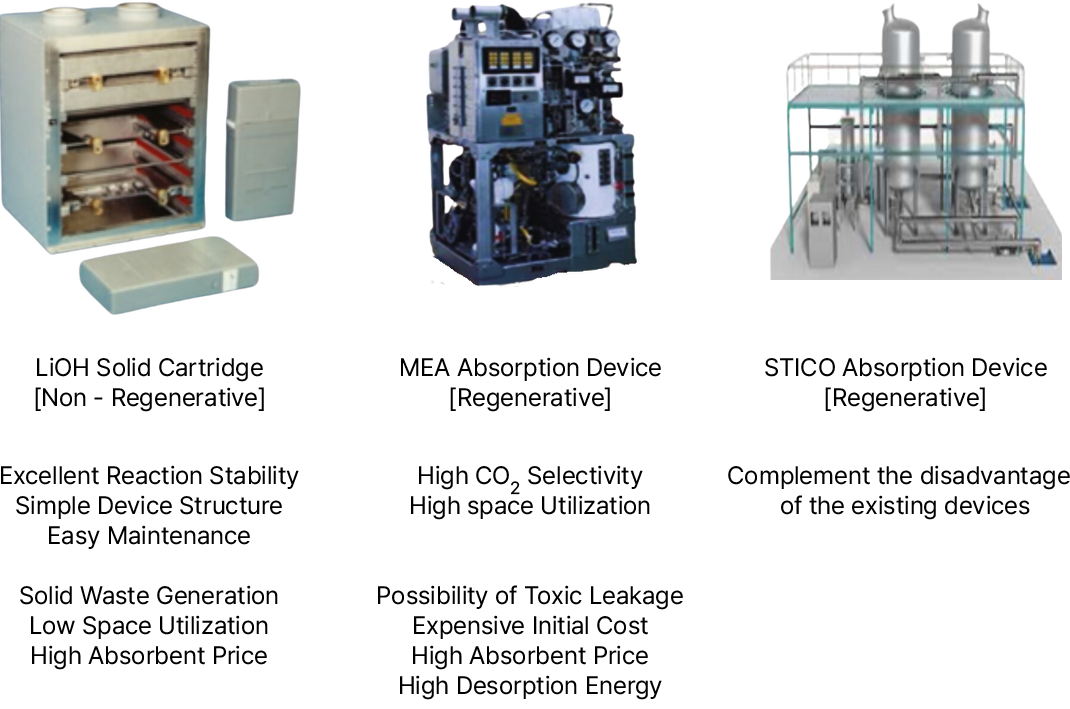

In the case of dry absorbents, if the CO2 Capture ability deteriorates, the chips must be replaced

manually, and

it is not easy to regenerate the saturated absorbent in a closed space. Chips to be charged are loaded

considering survival time and number of people, and already saturated chips also require space to be loaded.

Older dry device have the advantage of relatively simple structure and easy maintenance, but they require a

significant amount of space because they operate in a non-regenerative manner.

Amines, which are commonly applied in industry, have been used for a long time due to their high selectivity and

absorption rate for CO2. The absorbent is used dissolved in water, and can be regenerated by

desorbing CO2

depending on temperature. However, it has the disadvantages of high energy costs in the desorption process, side

effects resulting from oxidation and deterioration, risk of leakage of toxic gases, and high price.

In the case of STICO absorbent, which is a mixture of amino acid salt and alkali salt, a wet absorption method

is used like MEA. The absorption liquid is sprayed from the top of the tower and selectively captures

CO2 from

the gas flowing in from the bottom. It complements the existing shortcomings of MEA while maintaining equal or

better absorption performance. Renewable energy is low, resistant to oxidation and deterioration, and has low

risk of harm to the human body, ensuring safety. Additionally, it can be used for a long time and is

competitively priced.

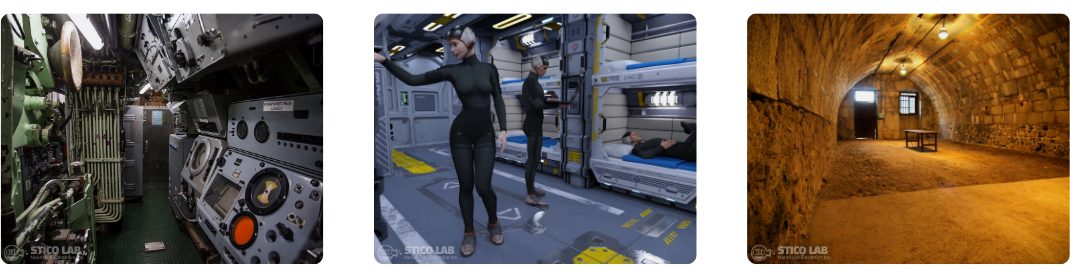

Submarine CO2 removal device design and prototype

[2019.05.10 ~ 2021.05.09]

- Substitute for solid adsorbents (LiOH cartridge)

- Reduction of Operation and maintenance cost

- Excellent performance compared to MEA absorbent solution

- Standardization and stabilization of device

Securing absorption and removal regeneration system