NEW TECHNOLOGY

STICO Lab is advancing several carbon capture and storage opportunities around the world to help support our commitment to the Paris Agreement.

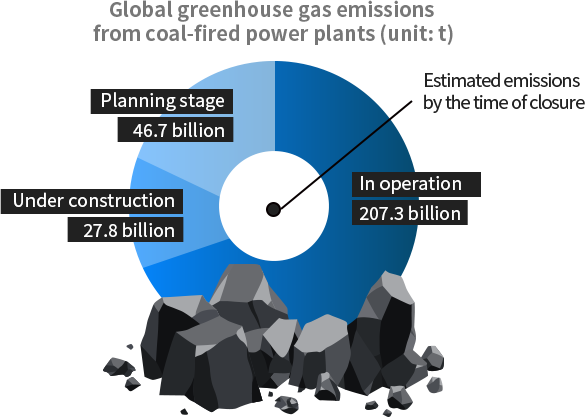

Global Coal Power Plant

CO2 Capture Plant Market Size

$ 2.8 trillion

(KRW 3,000 trillion)

$ 10 trillion or more

(Including Chemical / Cement / Steel Industry)

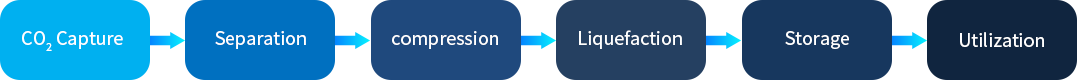

• Capture - Utilization

• Carbon Mineralization

Global Marine Fuel Market Size

$ 100 billion per year

(KRW 120 trillion)

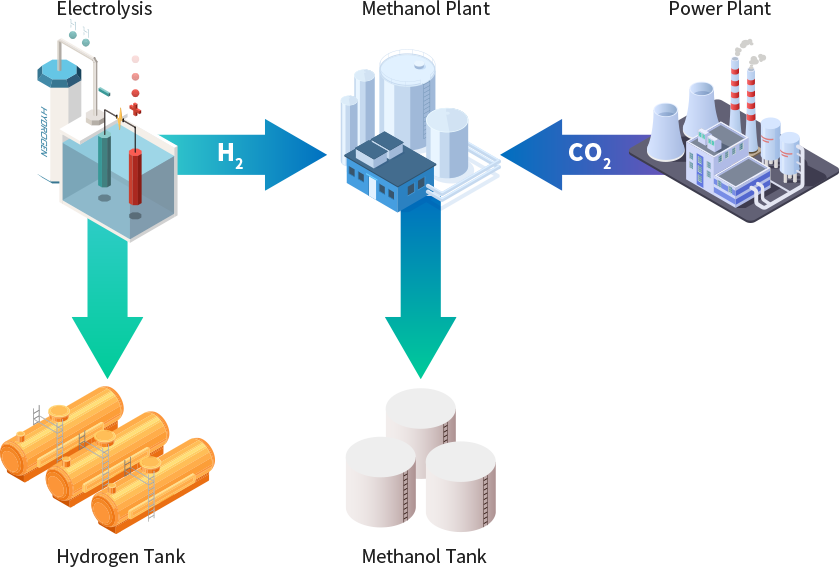

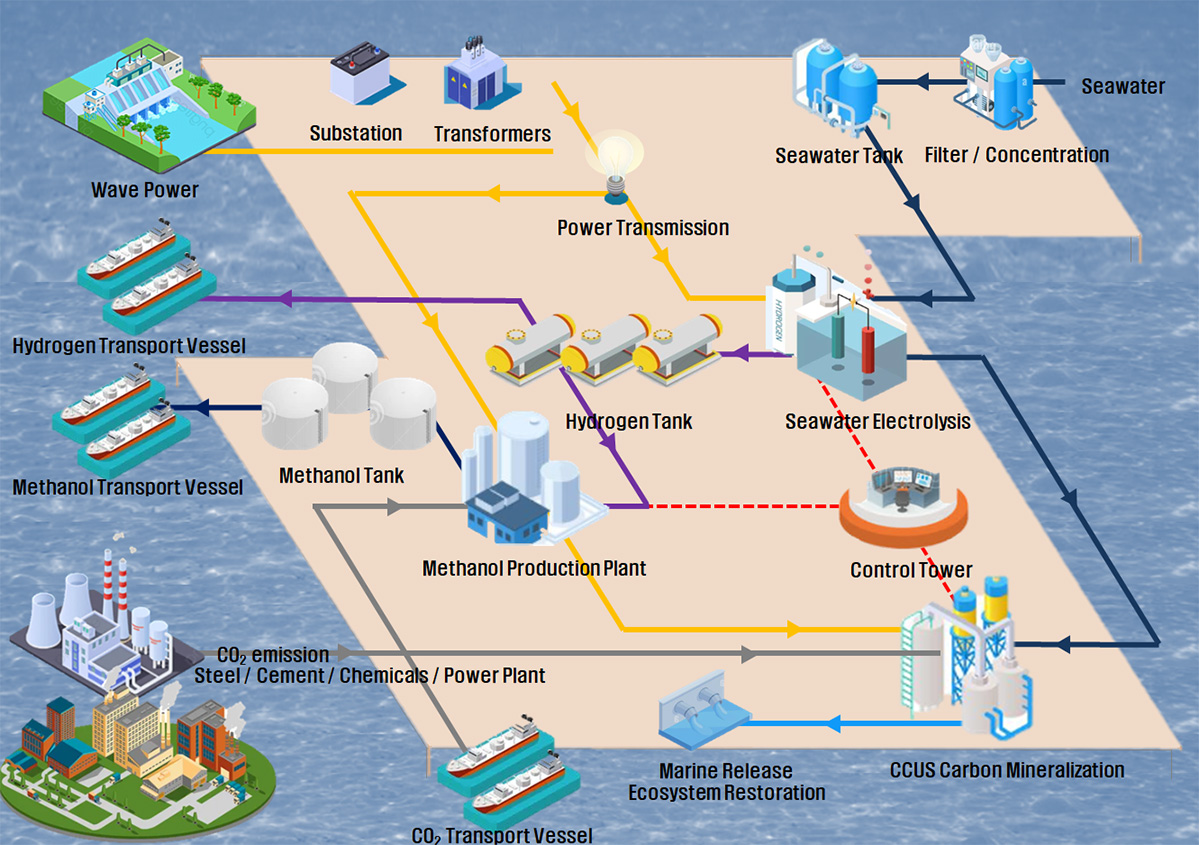

H2 from Seawater Electrolysis

CO2 from Industrial Plant

• Methanol / Hydrogen Fuel

• Industrial Power Supply

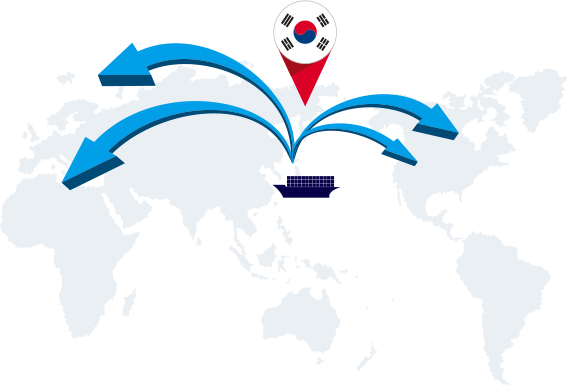

Domestic CO2 Transport Market Size

$ 18 billion per year

(KRW 20 trillion)

Limitations of Domestic CO2

export for EOR Utilization

• Use in Methanol Production

• EOR

Utilization of world-class domestic shipbuilding technology – Floating CO2

Capture

Plant (250MW, 500MW, 1000MW)

Reduced construction cost by 1/5 compared to onshore plants – Preoccupation in the

global market

Construction Investment Cost : 250MW - $200 million / 500MW - $400million / 1000MW -

$700million

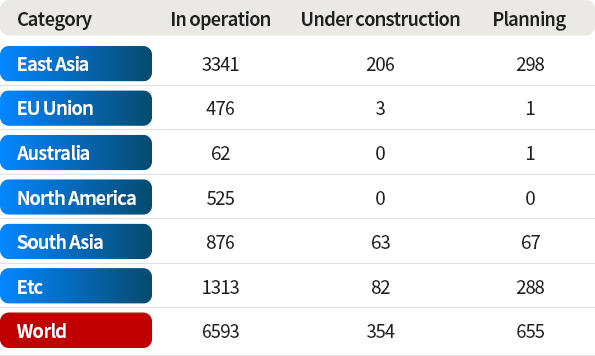

• Coal-fired power plants around the world : 7,000 unit (Operating + Under Construction)

• Average construction cost of floating CO2 capture plant : $ 400 million (Based on 500MW)

• Market size : 7,000 Unit x $ 400 million / unit $2.8 trillion (KRW 3,000 trillion)

• 10% Market share $280 billion (KRW 300 trillion)

Floating Combined Cycle Power Plant

World shipping companies – To order 50 methanol vessels by the end of this

year

UK CLARKSON predicts that by 2030 75-80% of the world's ships will use methanol fuel

National hydrogen industry development policy – 30 million tons of hydrogen

production per year

Hydrogen produced through seawater electrolysis can be used as new energy and can be converted into methanol through a chemical reaction with carbon dioxide. Green methanol and recycled methanol technology, which converts large amounts of carbon dioxide generated in chemi-cal plants, power plants, and steel mills directly into methanol without syngas, are expected to contribute to responding to climate change. Methanol is used as a synthetic solvent as well as a raw material for the manufacture of various chemicals and pharmaceuticals. It is also used as a clean raw material for shipping ships and as fuel for methanol fuel cells.

As the shipbuilding industry is accelerating the development and commercialization of next-generation eco-friendly fuel for ships that will follow liquefied natural gas (LNG), ‘methanol-powered ships’, which will serve as a stepping stone before the full-fledged offshore hydrogen market, are gaining momentum. Recently, as global shipping companies are increasing orders for large container ships that use methanol as fuel, competition for orders for methanol-powered ships is intensifying.

Previously, Musk, a world-class large shipping company, placed an order to Hyundai Heavy Industries in August 2021 to build eight 16,000 TEU container ships that use methanol as fuel by 2024 by 2024. Along with Musk, CMA CGM, a global 'top 3' shipping company, recently announced a plan to place an order for six new 15,000 TEU-class methanol dual-fuel new ships.

Captures 300 million tons, about 50% of Korea’s annual CO2 emissions → Requires 500 carriers

Expected boom in domestic shipbuilding and steel industry

Annual CO2 emissions in Korea

680 million tons (as of 2021)

CO2 Storage - Utilization

300 million tons (as of 2021)

Dual-Carrier (CH3OH/H2/CO2)

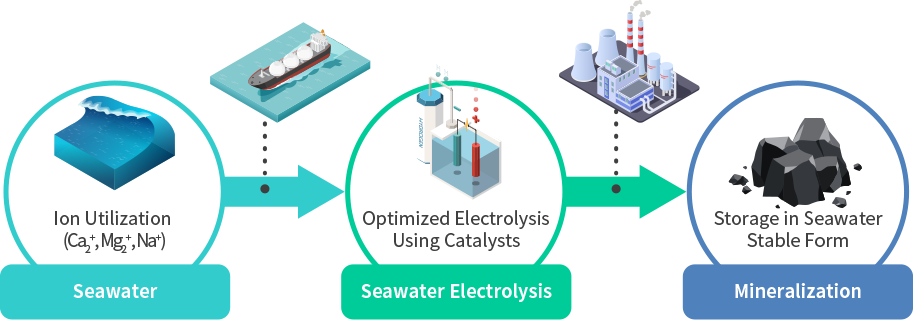

Element technology: Wave power renewable energy using seawater / Hydrogen new energy through electrolysis / Methanol production through the synthesis of hydrogen and carbon dioxide / Carbon mineralization through the reaction of seawater and carbon dioxide / Ocean alkaliza-tion and ecosystem restoration through carbonate discharge

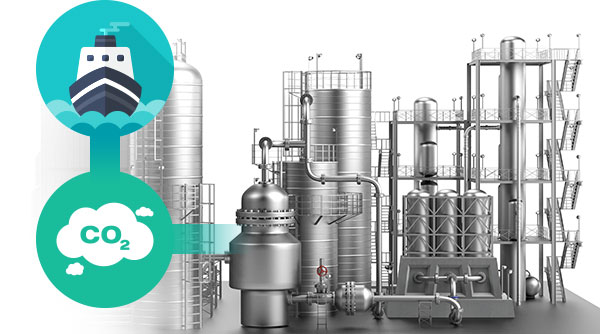

Responding to GHG (Green House Gas) emission regulations of IMO (International Maritime Organization)

The IMO aims to reduce ship GHG emissions by 50%

compared to 2008 levels by 2050

Seawater contains about 3.4 ‰ of salt. The seawater flowing into the electrolysis device installed on the ship reacts to generate metal hydrox-ide. A stable form of carbonate is produced through the reaction of the seawater containing the metal hydroxide prepared in this way with the carbon dioxide emitted from the ship stack. Carbonate generated through these chemical reactions becomes a resource that can restore the marine ecosystem by re-discharging it to the sea without the need for a separate storage facility.

When using 1 / 1,000,000 seawater in earth, 23.7 billion tons of CO2 reduction

The best way to achieve Net CO2 Zero

Currently, policies for reducing carbon dioxide in ships, a source of non-road pollution, focus on the production and utilization of liquefied carbon dioxide through the absorption-desorption regeneration process. However, considering space constraints, excessive energy consump-tion, economic feasibility, human harm and risk, We propose technology that can contribute to the marine ecosystem is more suitable.